Menu

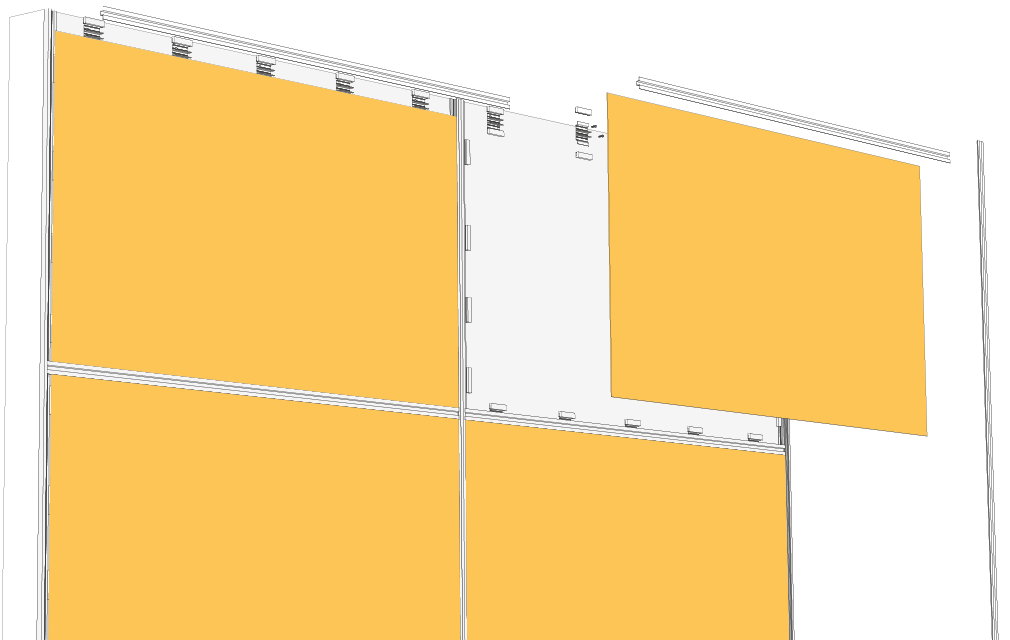

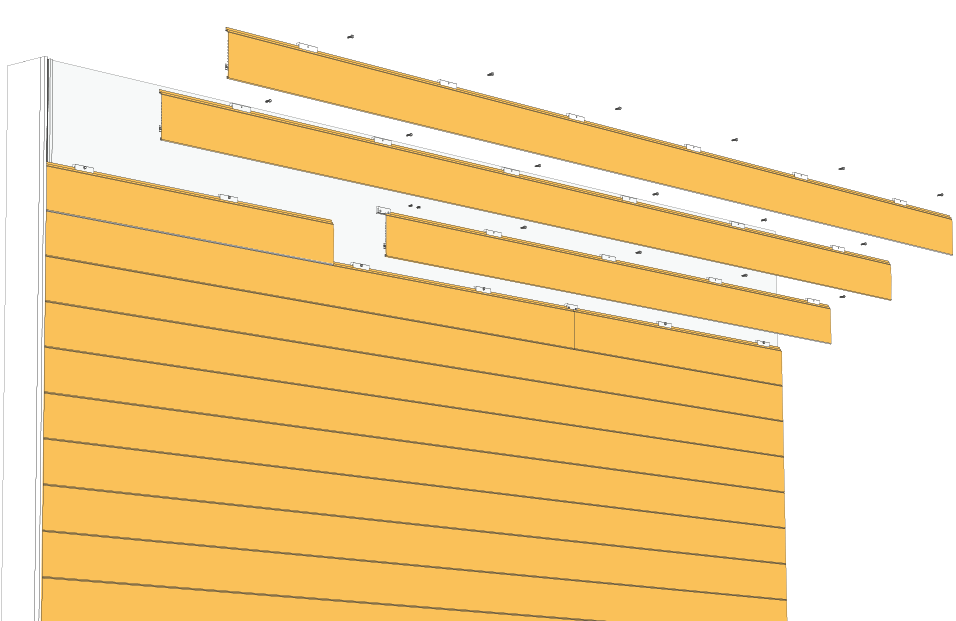

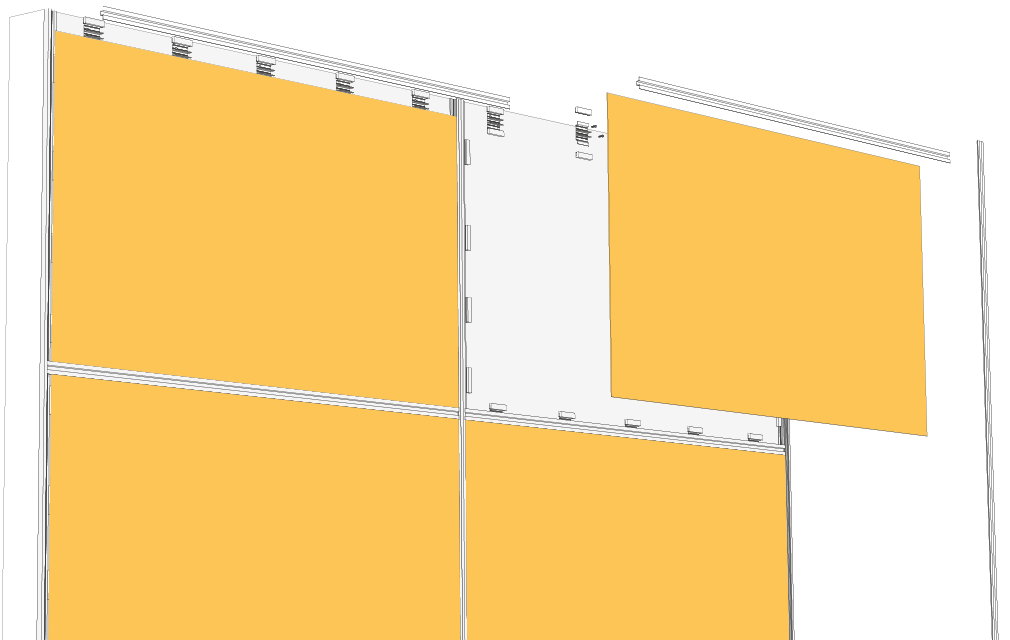

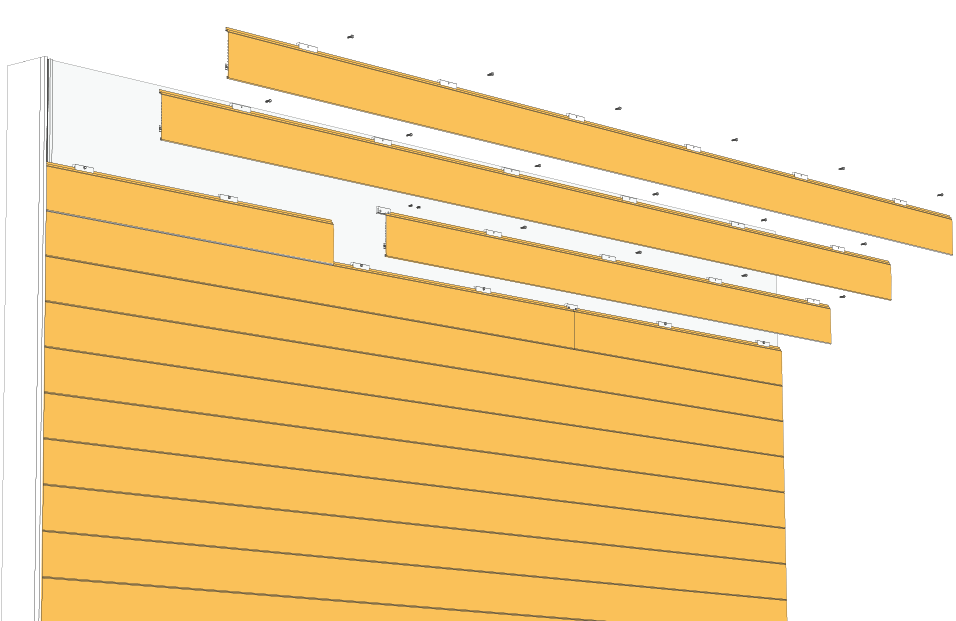

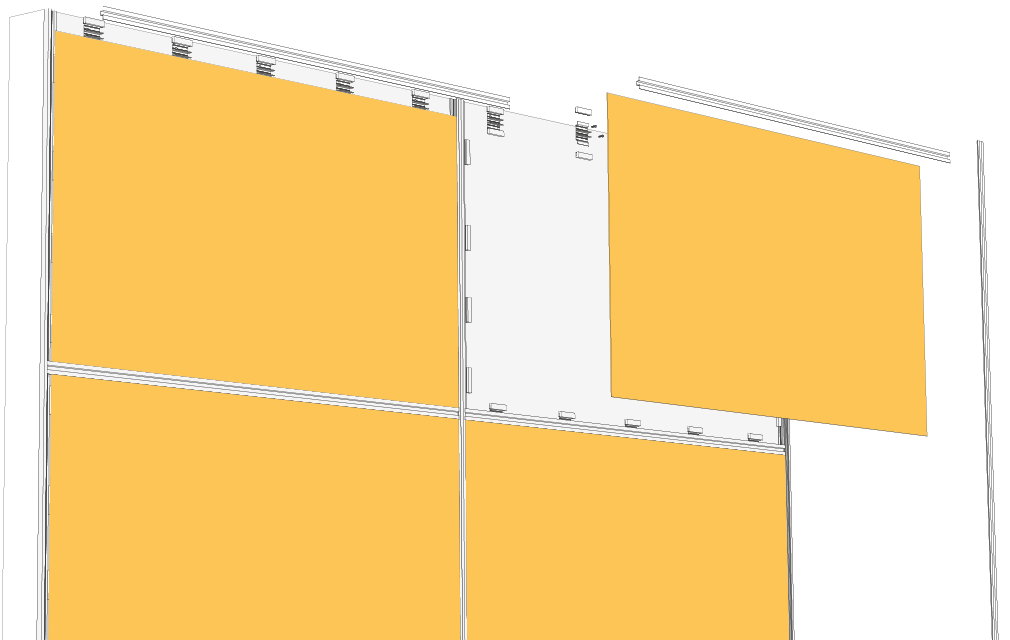

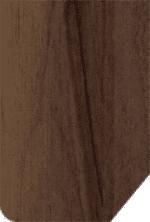

Instead of waiting for pre-fabricated parts, AL13® Panels are cut-to-fit on site. The system is secured using system frame components, allowing for on-the-fly changes.

Achieve a premium look without the financial constraints of route and return.

Cut-to-fit on site for increased flexibility.

With AL13® you can also replace individual panels easily and cost-effectively.

AL13® Panels are available in standard polyethylene (PE) or fire-rated (FR) cores. System components have built-in moisture management (pressure equalized rain screen).

9 solids, 4 metallics, 5 woodgrain. Unlimited possibilities.

SD323

SD301

SD302

SD304

SD327

SD330

SD303

SD333

SD334

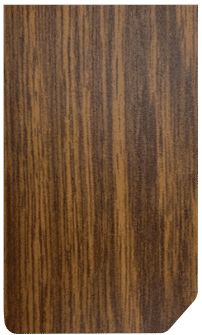

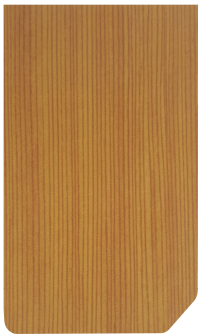

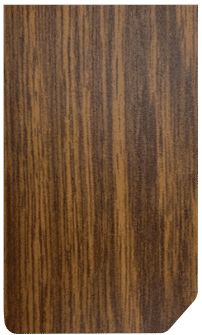

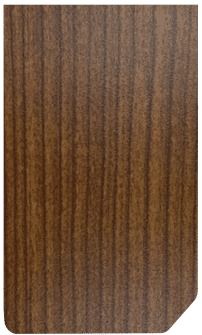

WD319

WD316

WD315

WD310

WD311

SD330

SD303

SD333

SD334

MC309

MC321

MC322

MC308

WD311

SD330

SD303

SD333

SD334

Classic profile design with 1/8 shadow line that matches real timber. AL13® Planks have a true woodgrain look & feel and also come in a variety of solid colors.

AL13® Planks are not a single product, but a certified rainscreen system. Designed to prevent the build-up of moisture between the siding and the exterior wall – avoiding water damage issues.

Easy to handle and rigid 12′ length planks allow a single installer to complete any project.

AL13® Plank System shares common framing components with AL13® Panel System to allow for a seamless transition between Plank and Panel.

5 popular woodgrains, a variety of standard colors.

716+1501/02

716+1101/02

733+2503/04

716+1406/01

733+1402/02

SD303

SD333

SD334

No proprietary off-site manufacturing. Better project management.

Instead of waiting for pre-fabricated parts, AL13® Panels are cut-to-fit on site. The system is secured using system frame components, allowing for on-the-fly changes.

Achieve a premium look without the financial constraints of route and return.

Architects choose AL13® when it comes to competitive bids on large projects, including institutional schools, multi-families, high rises, and national brand transformations.

Cut-to-fit on site for flexibility.

Half the weight of fiber cement.

If mistakes happen on-site, replacing pre-fab panels requires replacing the entire surrounding install, in addition to order wait time.

With AL13®, you can replace individual panels, not the entire pre-fab.

ULC-S134. ASTM E330. AAMA 508.

NFPA 285. CAN/ULC-S102. ASTM E84.

AL13® Panels are available in standard polyethylene (PE) or Class A2 fire rated (FR) core – the highest quality fire resistant panels. System components have built-in moisture management (pressure equalized rain screen).

SD323

SD301

SD302

SD304

SD327

SD330

SD303

SD333

SD334

WD319

WD316

WD315

WD310

WD311

SD330

SD303

SD333

SD334

MC309

MC321

MC322

MC308

WD311

SD330

SD303

SD333

SD334

We went back to the drawing board – we started with a blank sheet of paper with the goal of addressing 3 key features that other lookalikes have missed.

New profile behind the plank to increase rain screen functionality

Improved strength to weight ratio.

Classic profile design that allows for increased installation precision within 0.5mm (20 thou) for reduced risk of compression resulting from material expansion and contraction across the width of the plank.

6 popular woodgrains, a variety of standard colors.

716+1501/02

716+1101/02

733+2503/04

716+1406/01

733+1402/02

755+1815/09

SD303

SD333

SD334

No proprietary off-site manufacturing. Better project management.

Instead of waiting for pre-fabricated parts, AL13® Panels are cut-to-fit on site. The system is secured using system frame components, allowing for on-the-fly changes.

Achieve a premium look without the financial constraints of route and return.

Architects choose AL13® when it comes to competitive bids on large projects, including institutional schools, multi-families, high rises, and national brand transformations.

Cut-to-fit on site for flexibility.

Half the weight of fiber cement.

If mistakes happen on-site, replacing pre-fab panels requires replacing the entire surrounding install, in addition to order wait time.

With AL13®, you can replace individual panels, not the entire pre-fab.

ULC-S134. ASTM E330. AAMA 508.

NFPA 285. CAN/ULC-S102. ASTM E84.

AL13® Panels are available in standard polyethylene (PE) or Class A2 fire rated (FR) core – the highest quality fire resistant panels. System components have built-in moisture management (pressure equalized rain screen).

SD323

SD301

SD302

SD304

SD327

SD330

SD303

SD333

SD334

WD319

WD316

WD315

WD310

WD311

SD330

SD303

SD333

SD334

MC309

MC321

MC322

MC308

WD311

SD330

SD303

SD333

SD334

We went back to the drawing board – we started with a blank sheet of paper with the goal of addressing 3 key features that other lookalikes have missed.

New profile behind the plank to increase rain screen functionality

Improved strength to weight ratio.

Classic profile design that allows for increased installation precision within 0.5mm (20 thou) for reduced risk of compression resulting from material expansion and contraction across the width of the plank.

6 popular woodgrains, a variety of standard colors.

716+1501/02

716+1101/02

733+2503/04

716+1406/01

733+1402/02

755+1815/09

SD303

SD333

SD334

United States

Tel: +1 855 438 2513

Email: info@al13.com

Canada

Tel:+1 855 438 2513

Email: info@al13.com

Copyright © 2023 AL13® architectural systems